HOW AODD PUMPS IMPROVE SOFT-DRINK PRODUCTION

Manufacturers of carbonated soft drinks, fruit juices, teas and energy drinks are discovering that the most reliable, safe and energy-efficient technology for these operations are air-operated double-diaphragm (AODD) pumps, in many cases Saniflo™ Hygienic™ Series (HS) and FDA models from Wilden®.

THE UNITED States landscape is dotted with soft-drink production facilities, commonly known as canning and bottling plants that blend high-fructose corn syrup, various concentrates, different flavorings and phosphoric acid to create products that are ready for consumption.

In many instances, the global soft-drink market’s large multinational companies contract with bottling companies to produce their soft drinks in accordance to their tried-and true formulas. There are also littler mom-and-pop operations that produce on a less-grand scale, but still require the assistance of the canning and bottling company.

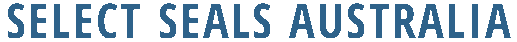

Type T21 Metric Pump Mechanical Seals

The Type 21, a general purpose seal, has become an industry standard with OEM designers.

Basic Tool to help ID the Mechanical Seal Type

Basic seal selection

This is just the first step to ID the correct seal type – further information my be needed depending on the application!

Progressive Cavity Pumps & Wastewater Sealing

SOME IMPORTANT questions about the advantages of progressive capacity pumps and what types of mechanical seals are used in wastewater applications are dealt within this article.

Double Checking Your Valves May Save Time & Improve System Performance

IRRIGATION CONTROL valves should always be placed up stream of the pressure regulator and filters. There are times, however, when this is not possible.

If such is the case, the pressure loss through the valve must be calculated and the “real pressure” to the first emitter determined.

Post-Season Checklist Helps Growers Tackle Needed Maintenance and Repairs

BEFORE SHUTTING down your irrigation system for the winter, experts suggest conducting a quick inspection – performing routine maintenance and making a plan for any necessary repairs.

“A thorough inspection can help identify potential problems that could result in costly delays or breakdowns next year,” said Evan Carlson, field engineer at Lindsay Corporation.

Valve Packing Friction: the Hidden Factor for Better Plant Performance

Pipeline rupture

IN MANY processes, valves are used as a way to control flow—but they also must seal leakage from the stuffing box and operate freely to keep the plant running properly.

Packing success and valve operability need accurate gland loading to perform correctly. Packing friction is a byproduct of tightening packing that needs to be compressed. If left unattended, issues can arise.

Power Bill Slashed at North Queensland Pump Station

Kilrie Gully Relift

A PUMP STATION in North Queensland has slashed its power bill by $20,000 a year, an audit has revealed.

Lower Burdekin Water (LBW) has saved tens of thousands on its power bill at its Kilrie Gully pump station, after implementing the findings of an Energy Savers Program audit.

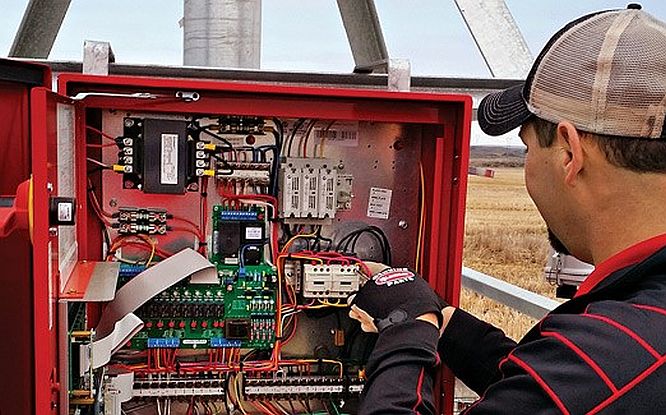

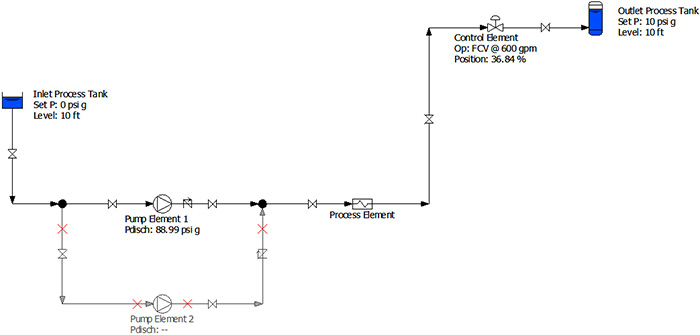

System Approach & Modeling Lead to a Reduced Impeller Diameter

Figure 1: Process system with one pump operating

EVERY ELEMENT found in a piping system falls into one of three categories: pump, process and control. The secret to understanding any piping system is to have detailed knowledge of the various pieces of equipment and how they work together.

For example, if a pump is not sized properly to meet the system’s process requirements, all the equipment within the system will be affected.

Murray Irrigation Commissions Modernisation Project

MURRAY IRRIGATION received $162 million from the Australian Government to commission a modernisation program that will transition the irrigation system from manual to predominantly automatic.

The not-for-profit company’s Private Irrigation Infrastructure Operators Program (PIIOP) spans its entire footprint and involves the upgrade of more than 3,400 structures comprising 2,100 outlets and 1,300 regulators.