How Mechanical Seals in Lobe Pumps Work

Mechanical seals in lobe pumps are quite widespread in many industries that involve a need for sanitary qualities and good resistance to corrosion. Among these industries there are food and beverage, pharmaceuticals, paper production or biotechnology.

Mechanical seals in lobe pumps are quite widespread in many industries that involve a need for sanitary qualities and good resistance to corrosion. Among these industries there are food and beverage, pharmaceuticals, paper production or biotechnology.

Lobe pumps are preferred because of their reliability and high efficiency, as well as for their steam-in-place features.

Rotary pumps are ideal for dealing with solid matters such as olives or cherries, as well as with pastes, slurry or liquids. Such pumps are the most effective when they are wet, but they can also function dry for a short time, if needed.

Rotary pumps are ideal for dealing with solid matters such as olives or cherries, as well as with pastes, slurry or liquids. Such pumps are the most effective when they are wet, but they can also function dry for a short time, if needed.

Mechanical seals in lobe pumps regulate the flow, therefore it doesn’t matter how pressure changes in the production process, the output will always be continuous and steady.

How Mechanical Seals In A Lobe Pump Works

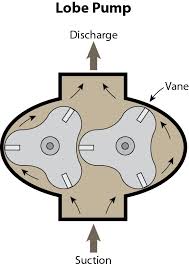

Lobe pumps aren’t very much different from pumps featuring external gear systems. In both cases, the fluid runs around the interior of the shell, the main difference being that lobe pumps don’t allow contact. In case of mechanical seals in lobe pumps, the fluid pressure is controlled by the bearing location and shaft deflection.

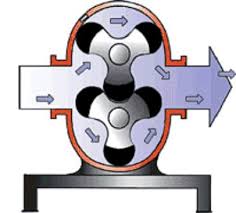

- When lobes exist the mesh, an expanding volume is created on the side where the fluid is drawn in, thus determining it to enter the cavity. Then, the fluid is trapped inside by the rotation of the lobes.

- The fluid flows through the space created between the lobes and the casing. without spreading between the lobes themselves.

- The fluid is eventually pushed out through the outlet opening, under the pressure created by the movement of the lobes.

The best advantage offered by lobe pumps is that they allow handling solids without destroying them. This is possible because there is not contact between the lobes and the product itself, thus enabling larger clearances than other pump types.

The best advantage offered by lobe pumps is that they allow handling solids without destroying them. This is possible because there is not contact between the lobes and the product itself, thus enabling larger clearances than other pump types.

This is what makes lobe pumps so widely used in the food processing industry. Other types of pumps don’t allow particles this size to pass through without getting damaged in the process. When using lobe pumps for handling high-viscosity fluids, a lower speed is required in order for the process to be smooth and successful.

This is what makes lobe pumps so widely used in the food processing industry. Other types of pumps don’t allow particles this size to pass through without getting damaged in the process. When using lobe pumps for handling high-viscosity fluids, a lower speed is required in order for the process to be smooth and successful.

Manipulating low-viscosity fluids is tricky, because the performance is diminished and the suction ability is significantly reduced.