Cartridge Mechanical Seal from Gland Packing

Original before conversion to cartridge mechanical seal

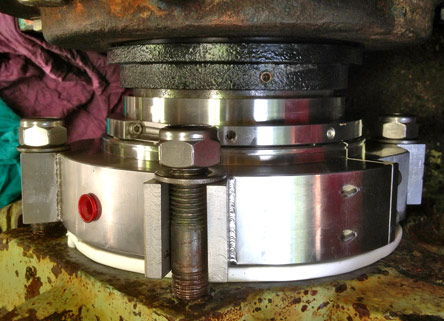

THIS GOLD COAST City Council pump was converted from gland packing to SEPCO XRS SPLIT SEAL

Cartridge Mechanical Seals Are The Modern Alternative

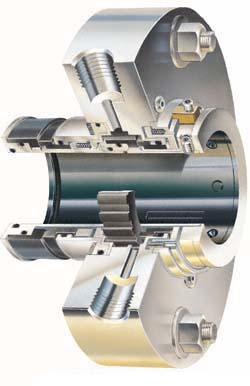

Cartridge seals are self-contained systems including a shaft sleeve, seal, and gland plate. The system is fitted onto the pump shaft as a constructed assembly, and no further fitting is needed.

Pump shaft housing prior to conversion to cartridge mechanical seal

Cartridge seals are an effort to over-come the fitting issues of conventional seals. Tangential tappings for presenting fluids into the gland cause less disruption to the seal face than the radial tappings typically discovered on pump units.

For a packing gland this might not be important however to a mechanical seal it can be another adverse condition with which to cope.

The setting position of the seal is set by the cartridge design, but the seal device need to not be screwed to the shaft till the gland plate is secured to the pump and any adjustments made to the shaft position. As soon as this has been finished the set screws can be tightened and the spacers eliminated.

So, what can fail. The design works to get rid of numerous of the common causes of seal failure on installation and since the seal exists on its own shaft sleeve any damage that may be triggered by a standard seal to the pump device is also removed.

The trouble is that the seal needs to be really compact to suit the offered area. Seals need mass to produce as high a co-efficient of inertia as possible. The greater the mass the less affected the rotation parts are to transient vibrations.

Such vibrations will be taken in lessening the tendency to vibrate the seal deals with apart.

Detail shot of XRS split-mechanical seal

If the seal faces open then they are quickly susceptible to contamination from the myriad dirt bits swirling around your plant, keep in mind.

When the seal faces close those fragments are trapped, in a carbon ceramic mix the bits end up being embedded in the carbon and begin to score away at the mating face.

I should make it clear that all seals suited gland boxes pre-owned by a packing gland are subject to these problems.

All seals are a compromise on measurements, they are no excellent if they do not fit!

The certain issue of the cartridge seal is that the components further decrease the offered area into which a huge enough mass can be inserted to deal with vibrations.

If you are going to use this kind of seal then it is necessary that the unit you fit it to is in great condition. Bearings within tolerance, shaft unbent, impeller in well balanced condition, system not experiencing the effects of cavitation.

You will pay a great deal of money for a very first course seal device, so ensure you accomplish all the benefits by looking into the pump unit for defects.

I arranged an upgrade for a series of boiler water circulating pumps dealing with a main furnace for a Naval base complex. The refurbishment of the system was performed by engineering specialists.

Cartridge Seal Cutaway

To ensure that as couple of troubles took place as possible cartridge seals were specified. Fit and forget. One of the four seals failed with 14 days of fitting.

The boiler house operator reported an unusual “buzzing” sound coming from the pump unit. It was a minutes work to identify the possible cause, the noise was coming from the rubber shaft combining. In addition the seal released a periodic high pitched scream and steam might be seen puffing from the gland area.

The hot water in the system flashed off to steam across the seal face so triggering the seal face to run dry. The emerging steam can be seen at the gland and the howling noise suggested that the seal had actually re-seated.

The fault lay with the re-installation of the pump system. There was absolutely nothing wrong with the seal setup and the other three seals ran for years without any problem. The 4th seal had to be re-built and when the motor feet had been machined, it too ran for years trouble-free.

It just takes a few minutes to bring out the setup checks, so why waste time reconstructing pump units a 2nd time when you can get it ideal first time around?

Cartridge mechanical seal being fitted

Cartridge seals are an effort to over-come the fitting issues of traditional seals.

Tangential tappings for presenting fluids into the gland cause less disturbance to the seal face than the radial tappings commonly discovered on pump systems.

I need to make it clear that all seals fitted into gland boxes secondhand by a packing gland are subject to these problems.

The hot water in the system flashed off to steam across the seal face so causing the seal face to run dry.

There was nothing incorrect with the seal installation and the other 3 seals ran for many years without any difficulty.